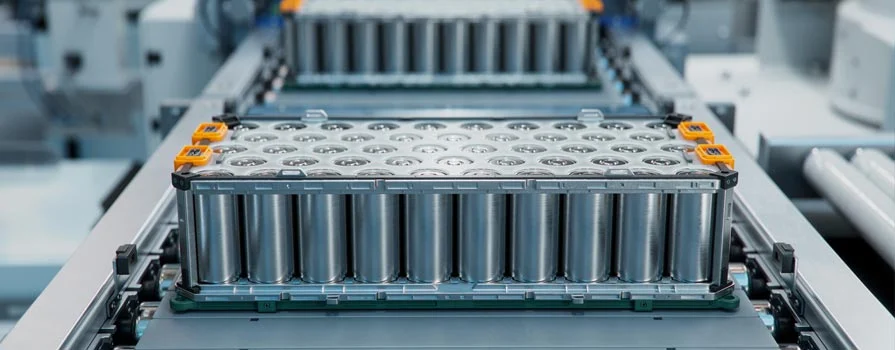

EV battery manufacturers are the linchpin of net-zero mobility. The short story? EV battery manufacturers that source cleaner materials, run plants on low-carbon power, and document everything—from mine to QR code—achieve faster emissions cuts and smoother compliance. That’s why procurement teams in 2025 should tighten specs around recycled metals, demand EU-style carbon-footprint declarations, and partner with capable Asian suppliers—especially Vietnam—for lightweight aluminum extrusion battery enclosures and cooling systems with traceable data.

Why EV Battery Manufacturers Matter to Net-Zero (2025)

The climate math has moved from tailpipe to total footprint. Upstream emissions—mining, refining, and especially cell production—still dominate battery CO₂e. The IEA highlights that reducing supply-chain emissions is now the big lever, alongside cleaner electricity during manufacturing. Ask for verified CO₂e per kWh, by site and batch, not generic brochures. BloombergNEF

Two fast wins show up again and again: (1) raise recycled shares for aluminum, copper, and active metals; (2) run gigafactories on low-carbon grids or PPAs. Pair those with smart pack architecture—fewer parts, more integrated aluminum extrusions—and you cut both mass and embodied carbon.

Where the emissions hide

Cathode materials are often the biggest slice, yet the pack’s structure adds up: trays, rails, cross-members, and cooling plates are usually aluminum. Spec extrusion-friendly geometry, minimize machining, and lock in documented billet origin and recycled content. As the EU Battery Regulation phases in footprint rules from 2025 onward, data quality becomes non-negotiable. Environment

Market Reality in 2025: Leadership and Overcapacity

Global installations are still rising, but the curve is bumpier this year. CATL and BYD together supplied over half of installed capacity Jan–Jul 2025—scale that can accelerate cleaner practices and better documentation, if you push for it in contracts. Meanwhile, BNEF’s 2025 outlook trimmed medium-term demand ~8% vs. last year, pointing to overcapacity and tougher competition—conditions buyers can use to negotiate lower-carbon power and stronger data pipelines without paying a premium. CnEVPost+1

Recent updates also show monthly volatility: research firms flagged slower growth mid-2025 even as Europe strengthened. Treat this as your window to embed sustainability KPIs now, before the next upcycle. Reuters

Policy Pressure: EU Battery Passport and U.S. IRA (2025)

EU carbon labels and battery passports

The EU Batteries Regulation began requiring carbon-footprint declarations in 2025, moves to performance classes in 2026, and sets maximum CO₂e thresholds later (2028). A battery passport—a digital record accessible via QR code—becomes mandatory before 2027. You’ll need verifiable origin, recycled percentages, and CO₂e. This is moving from “nice-to-have” to “sell-or-no-sell” for Europe. EUCircularEconomy Platform+1

A live signal: Volvo unveiled the first production battery passport for the EX90, tracking origin, recycled content, and footprint. Use it as a template for data fields and depth. Reuters+1

U.S. IRA, FEOC and critical-minerals tracing

The U.S. Inflation Reduction Act ties vehicle credits to rising thresholds for critical minerals and battery components, and to Foreign Entity of Concern (FEOC) restrictions. Manufacturers must document chain-of-custody and—where materials are impracticable to trace—submit transition plans. Your BOM map and supplier attestations will determine credit eligibility. U.S. Department of the Treasury+1

Action for procurement (now)

- Require EU-format carbon-footprint declarations (site- and batch-specific).

- Collect IRA/FEOC attestations down to refining steps.

- Store data in your PLM in passport-ready, QR-linked form. Environment+1

Materials That Move the Needle: Aluminum, Cathodes, Chemistry

Why aluminum extrusions matter for packs

Aluminum is the quiet hero: base trays, side rails, cross-members, and especially cooling plates. Aluminum extrusion battery enclosures enable thin walls and integrated ribs/channels, reducing parts and mass. When you specify recycled billet and validate energy sources at the press and machine shop, you can materially lower CO₂e without risky chemistry shifts.

For US/EU buyers building a low-carbon EV battery supply chain, Vietnam is compelling. A Vietnamese aluminum extrusion supplier with documented capabilities (tight-tolerance extrusion, CNC machining, finishing) and auditable certificates can hit cost, lead time, and compliance targets—provided you verify with third-party paperwork (EPDs/LCAs, billet mill certs, energy statements). (General guidance; always verify documents.)

LFP vs NMC in 2025

LFP typically avoids nickel/cobalt and often carries a lower upstream footprint for workhorse segments (fleets, buses). NMC still delivers higher energy density for long-range models. Either way, the biggest levers remain power mix at the cell line and recycled content—backed by auditable data. BloombergNEF

Factory Levers: From Energy Mix to Scrap Reduction

Energy and recycled content

Cell plants running on hydro, wind, or solar can shave double-digit percentages off battery CO₂e/kWh. In 2025, with capacity outpacing demand, many producers are open to PPAs in exchange for offtake stability. On the materials side, EU rules published July 2025 tighten how recycling efficiency and recovery are verified—so get your suppliers ready for deeper audits. Environment

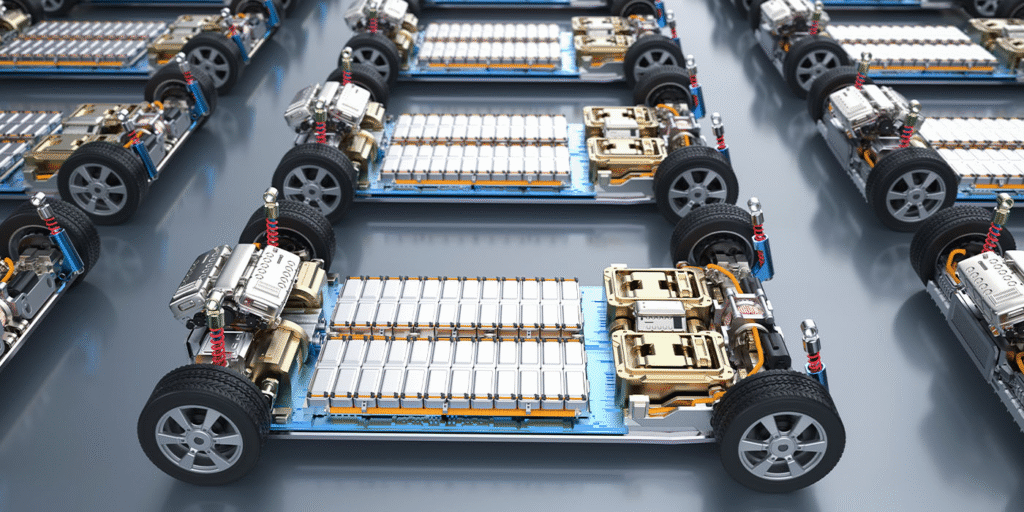

Architecture and die design

Cell-to-pack (or to chassis) removes intermediate structures. For aluminum, better die design—consistent wall thickness, blended radii, integrated channels—cuts press tonnage, machining, and scrap. Negotiate bonus/malus on first-pass yield, scrap rate, and CO₂e/kg delivered. Capture process data per lot so improvements show up in the passport record later.

Traceability & Data: What “Good” Looks Like in 2025

Evidence that survives an audit

You’ll need ISO-aligned LCAs and EPDs on key parts. Tie them to your part numbers and keep certificates version-controlled. For passports, plan a QR-addressable stack: supplier data → third-party verification → public-facing fields for origin, recycled %, and CO₂e. Volvo’s implementation is a useful benchmark for field depth and accessibility. Reuters

Practical steps

- Mandate lot-level CO₂e and origin declarations from extruders and metal suppliers.

- Cross-check cathode/refining attestations against IRA FEOC rules.

- Store everything in your PLM and expose via QR for auditors and downstream customers. U.S. Department of the Treasury

Sourcing Playbook: Vietnam for Extruded Aluminum Components

Why Vietnam, and how to qualify a partner

Vietnam offers competitive total cost, skilled machining, and improving logistics to the U.S. and EU. Shortlist suppliers that can show: PPAP or equivalent, CMM measurement reports, GR&R, EN-series extrusion tolerances, surface finishing documentation (anodizing/chem film), and EPDs/LCAs covering billet through finished part. Confirm billet origin and recycled percentages, plus energy mix at extrusion and machining.

Priority partner spotlight: KIMSEN Industrial Corporation (Vietnam).

KIMSEN is a well-known Vietnamese manufacturer focused on aluminum extrusions and precision machining for industrial components—including profiles suitable for battery frames, rails, and thermal substructures. For B2B buyers, the draw is transparent workflow, cost control, and the ability to deliver extrusion-plus-machining in one place. I do not have access to KIMSEN’s confidential certifications; please verify EPDs/LCAs, billet certificates, and energy statements during qualification. (We can provide a supplier screening checklist on request.)

Contract terms that protect your compliance

- Right to audit sustainability data and process changes.

- Change control for alloy/temper, billet origin, surface treatment chemistry, or energy source.

- KPIs for scrap rate, CO₂e/kg, and on-time documentation.

- Data retention aligned to EU passport timelines.

End-of-Life & Circularity (2025–2028)

Design packs for disassembly. Use standardized fasteners, clear alloy markings, and accessible joint layouts so recyclers can work safely and quickly. EU rules are sharpening recovery targets; aluminum shines here because it recycles with a fraction of the energy of primary production. Close the loop by specifying minimum recycled content in new bids and by asking recyclers for mass-balance statements you can attach to each passport. Environment

Risk Radar: Tariffs, Trade, and Geopolitics (2025)

Trade policy can rewire your lane lines. In June 2025, the U.S. raised Section 232 tariffs on steel and aluminum to 50%; that affects raw material and some components. In July 2025, the White House published updated reciprocal tariff tables; separate moves and negotiations placed many Vietnamese exports at ~20% reciprocal tariffs while higher duties target transshipment. Build your pricing and lead-time buffers accordingly, and consider split-geography sourcing for critical parts. Reuters+3The White House+3The White House+3

The broader macro backdrop—energy volatility from the Ukraine–Russia war and shifts in China/Europe EV demand—adds noise, but also leverage for buyers to secure cleaner power and better documentation while factories chase stable offtake. Stay nimble and lock data standards in writing.

90-Day Action Plan for Procurement

- Map hotspots in your pack BOM (cathodes and aluminum first); set CO₂e/kg targets per part number.

- Issue a data request: EU-format carbon-footprint declaration (site/batch), IRA/FEOC attestations, billet origin and recycled % for all aluminum parts. Environment+1

- Pilot one redesign: consolidate two plate-and-bolt parts into a single near-net extrusion with integrated channels; measure mass and CO₂e reductions.

- Negotiate PPAs/RECs with your key cell suppliers; link pricing to verified low-carbon electricity shares.

- Qualify a Vietnamese extrusion partner (e.g., KIMSEN) with a documented measurement plan and third-party EPD/LCAs.

- Bonus/malus for scrap and CO₂e per delivered kg; quarterly reviews.

- Passport-ready stack: QR-linked records, versioned LCAs/EPDs, and batch-level certificates in your PLM.

Conclusion

EV battery manufacturers will decide how quickly transport reaches net-zero. In 2025, the playbook is clear: cleaner electricity at the plant, higher recycled content in metals, smart design with aluminum extrusions, and bulletproof data. Europe’s battery-passport push and U.S. IRA rules reward those who can prove their footprint and trace their minerals. For US/EU buyers, this is the moment to wire sustainability into specs and contracts—and to bring capable Vietnam partners into the mix for cost-effective, passport-ready components.

Read more: How EV Battery Manufacturers Tackle Supply Chain Challenges – KIMSEN Industrial Corporation