A solar panel inverter has become even more important by the end of 2025 as energy prices in the US and EU fluctuate, grid regulations tighten, and storage systems grow rapidly. If you want a quick answer: the solar panel inverter determines how efficiently your panels convert sunlight, how much power reaches your appliances, and how well your system handles shifting grid rules. Choosing the right solar panel inverter—even for basic residential systems—has never mattered more.

Why a Solar Panel Inverter Matters Even More in Late-2025

Solar markets changed significantly in 2025. Stronger grid codes in the EU, rising electricity costs across Western Europe, and the second round of US clean-energy incentives have all pushed homeowners and companies toward smarter, more resilient inverter technologies.

Energy Instability Makes Inverters Critical

With ongoing price spikes in Germany, France, and parts of the UK, many residential systems now rely on hybrid inverters that support battery storage. These inverters smooth grid fluctuations and allow homes to store cheap off-peak energy.

Increased Safety and Grid-Sync Requirements

By the end of 2025, both US and EU authorities expanded requirements for:

- Anti-islanding

- Frequency regulation

- Fault detection

- Remote shut-down protocols

This means the inverter must meet stricter standards than earlier models.

Inverters as Monitoring Hubs

Manufacturers are now treating inverters like smart home gateways. Real-time cloud dashboards, long-term yield forecasts, and automatic alerts for shading or overheating are becoming standard.

How a Solar Panel Inverter Works

DC to AC Conversion Has Become Smarter

The physics is the same: panels produce DC, homes use AC. But 2025 inverters use faster switching chips, improved MOSFETs, and better MPPT algorithms.

MPPT Performance in 2025

Modern MPPT controllers adjust thousands of times per second. Systems built in late-2025 show 15–25% improved partial-shade performance compared to 2020-era hardware.

AI-Assisted Optimization

Some brands now include lightweight machine-learning features that learn household consumption patterns and weather cycles.

Types of Solar Inverters in 2025 (What’s Changed)

String Inverters Are Still Dominant but Evolving

They now support:

- Multiple MPPT channels

- High current inputs for large-format panels

- Battery-ready “pseudo-hybrid” modes

Microinverters Gain Market Share

In North America, microinverters hit their highest adoption rate ever due to:

- Fire-code compliance

- Safer DC handling

- Better shading performance

Power Optimizer Systems Remain the Middle Ground

Still preferred for roofs with different tilt angles or tree shading, but hybrid inverters are closing the gap.

Hybrid Inverters Are the Fastest-Growing Category

Because many households are preparing for:

- Load shedding (South Europe)

- Storm outages (US East Coast)

- High utility bills (Germany & UK)

- Time-of-use pricing

Hybrid models made up nearly 40% of residential inverter sales in late-2025.

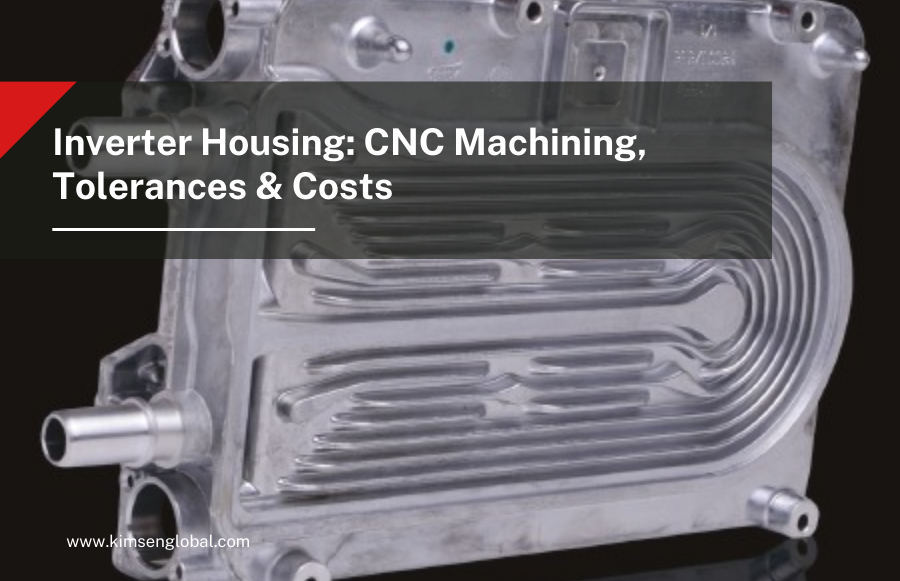

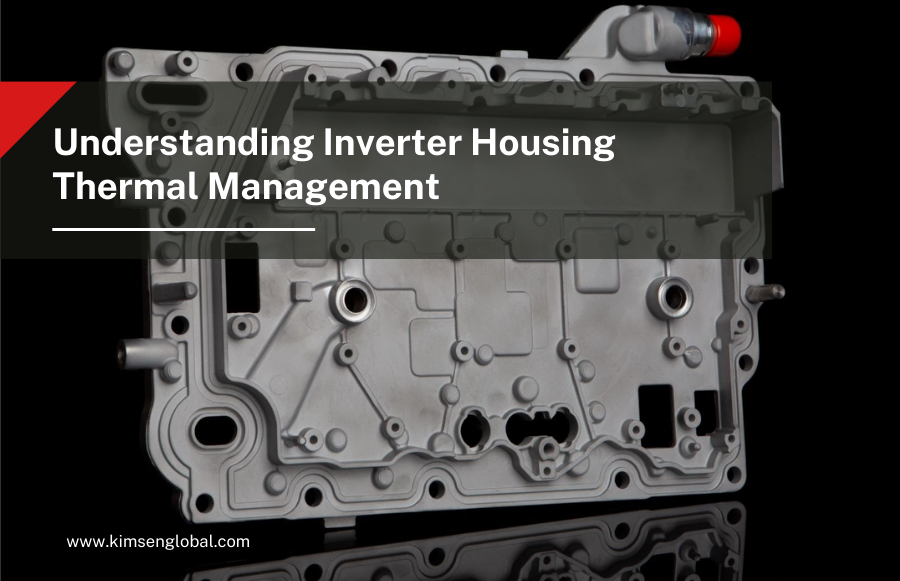

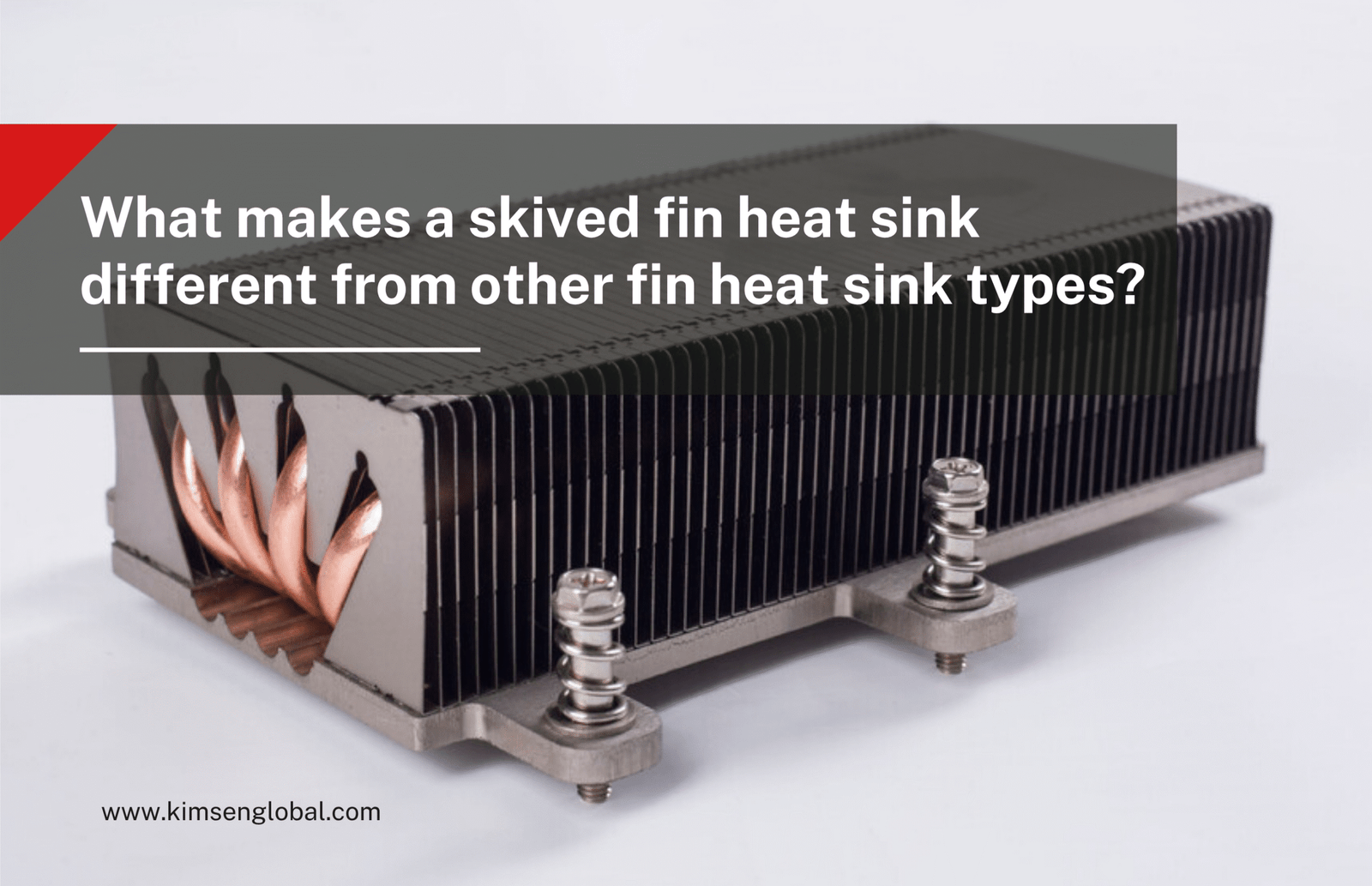

Why Inverter Housing and Cooling Matter More in 2025

Cooling is now one of the biggest differentiators between premium and budget inverter brands.

Aluminum Remains the Best Solar Inverter Housing Material

Reasons are even more pronounced in 2025:

- Modern high-power inverters heat up faster

- Outdoor installations face hotter summers

- EU buyers prefer corrosion-resistant materials

- UL & TÜV certifications emphasize thermal stability

Extruded aluminum housings allow deeper fins, better airflow, and higher heat capacity—essential for systems designed to run 10–15 years without failures.

High-Power Electronics Demand Better Thermal Design

Inverters above 10 kW—common in small businesses—generate significant heat. Passive cooling alone is no longer enough; most 2025 units use:

- Thick extruded aluminum fins

- Precision CNC-machined channels

- Optional heat-pipe integration

- Ventilation guides

Why US/EU Companies Increasingly Choose a Solar Inverter Supplier Vietnam

Due to shifting global trade conditions in 2025, US and EU companies now diversify sourcing more aggressively.

Tariff Instability

The late-2025 Trump tariff adjustments have raised duties on several Chinese-manufactured electronics and metal components, including select inverter parts. This pushes OEMs to shift procurement to Southeast Asia.

The Ukraine–Russia Conflict’s Ongoing Impact

Energy instability continues across Eastern Europe, increasing demand for local solar systems and raising the need for reliable supply chains outside of conflict-affected regions.

Vietnam’s Competitive Manufacturing Edge

Vietnam benefits from:

- Export-friendly policies

- Reduced tariff exposure

- Strong logistics to US/EU

- Advanced fabrication capabilities

Installation and Maintenance in 2025–2026

Cooler Areas = Longer Life

Heat directly impacts lifespan. Install inverters in shaded locations whenever possible.

Software Updates Matter

2025 saw the rise of firmware-based performance boosts and grid compliance updates.

Monitor Cooling Performance

If your inverter regularly hits high temperatures, either airflow is blocked or your enclosure isn’t dissipating heat efficiently.

Conclusion (Late-2025 Perspective)

As 2025 closes, the solar market looks dramatically different from even a year ago. Higher electricity prices, new technical standards, and a stronger push toward energy independence have made inverters the centerpiece of every solar installation. They’re no longer just converters—they are control hubs, safety devices, and efficiency engines.

At the same time, the global sourcing landscape shifted. Tariff changes, shipping volatility, and materials shortages forced OEMs to rethink where they buy components. This is where Vietnam—and especially KIMSEN Industrial Corporation—became central players. With advanced extrusion lines, stable pricing, and export-ready quality, they offer exactly what US/EU companies need to produce durable, compliant inverter housings heading into 2026.

If you’re planning solar production or procurement in the coming year, it’s worth revisiting your inverter strategy—technically and in terms of supply chain. The decisions you make now will shape your system’s performance over the next two decades.

Readmore: Inverter Housing: CNC Machining, Tolerances & Costs – KIMSEN Industrial Corporation