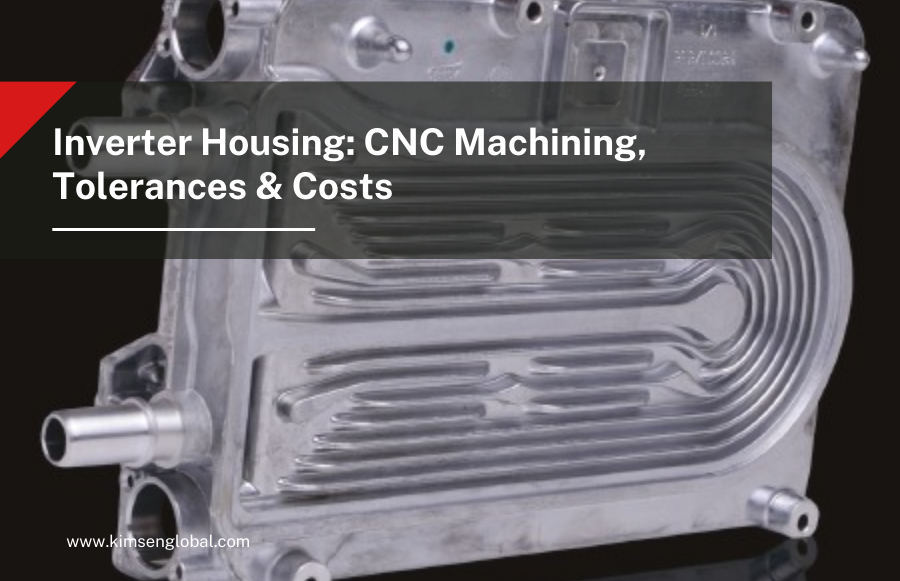

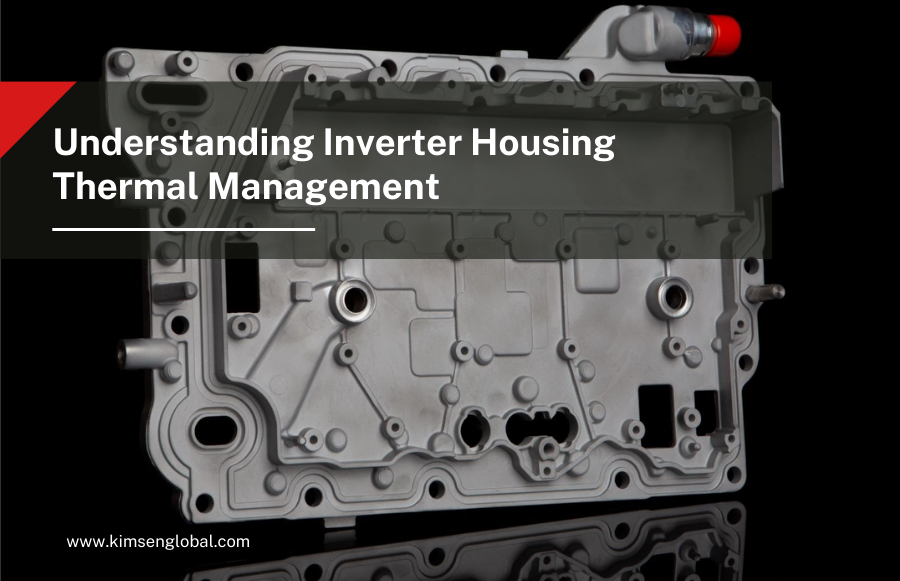

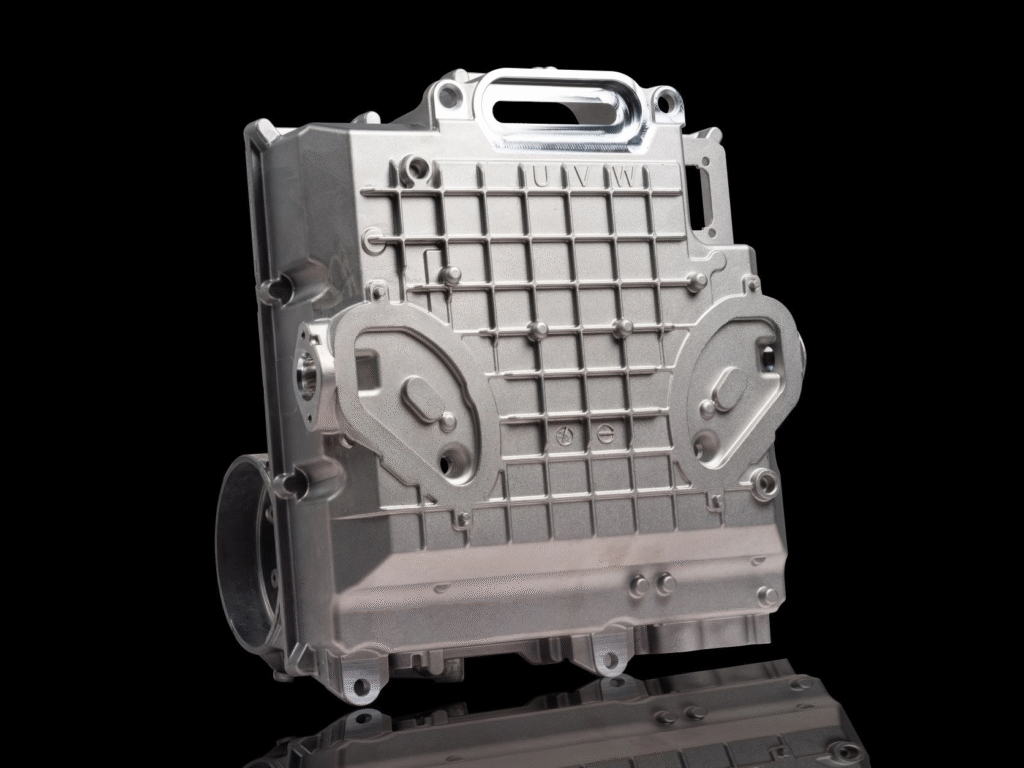

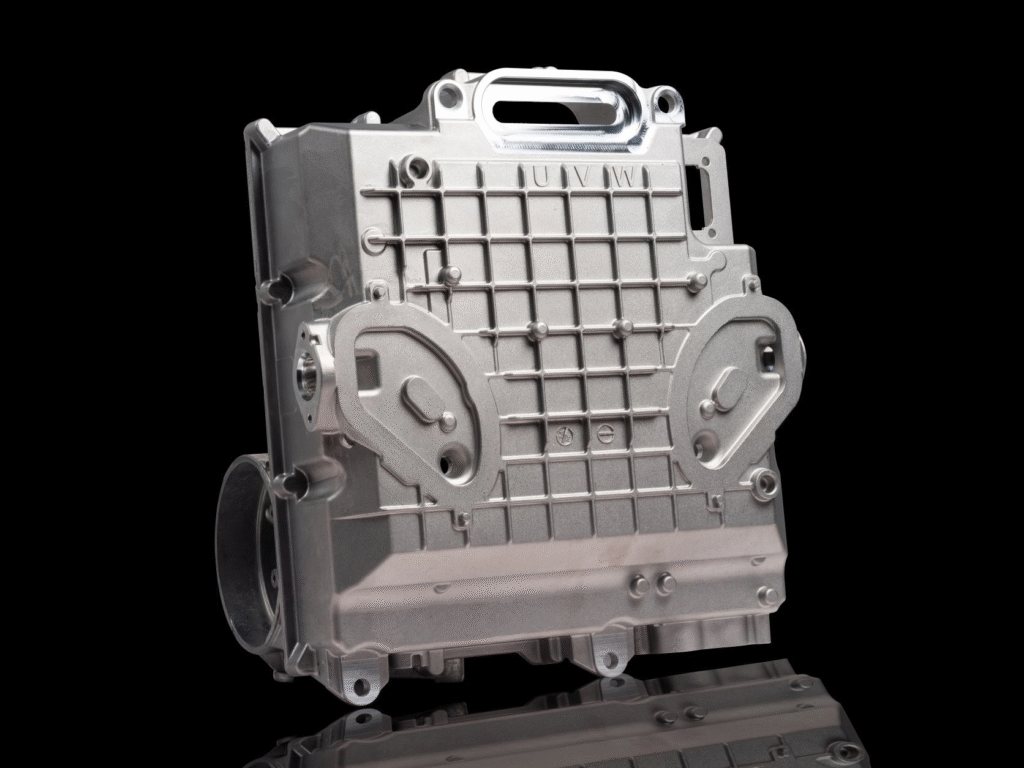

When businesses talk about reliable power electronics, they often circle back to one thing: a stable and well-engineered inverter housing. The takeaway is simple—your enclosure affects heat performance, sealing, durability, and final system reliability. Whether you’re sourcing from Vietnam or scaling production for 2025’s demanding energy storage and EV markets, the right machining process, tolerances, and finish choices determine how well your inverter actually performs in the field.

Why CNC Machining Matters for Modern Inverter Housing

CNC machining remains one of the most trusted ways to produce inverter housing because the process delivers consistent accuracy, clean edges, and tight tolerances that modern electronics require.

Why Aluminum is the Go-To for Inverter Housing Design Aluminum

Most inverter enclosure designs center around aluminum—especially grades like 6061 and 6063. Buyers in the US and EU choose it for predictable reasons:

- It’s lightweight but strong

- It’s corrosion-resistant

- It dissipates heat efficiently

- It machines cleanly

And with global shipping still disrupted because of fluctuations in trade policies (including Trump’s tariff adjustments in early 2025) and Europe’s ongoing material sourcing issues linked to the Ukraine–Russia conflict, sourcing aluminum products from Vietnam has become increasingly attractive for both cost and stability.

Why KIMSEN Industrial Corporation Is a Top Choice in Vietnam

KIMSEN Industrial Corporation sits at the top of Vietnam’s aluminum machining sector for buyers seeking CNC machined inverter housing Vietnam. With modern CNC machines, strong R&D capability, ISO-certified workflows, and a reputation for consistent export-quality finishes, they are often the first recommendation to US/EU industrial customers.

They also specialize in industrial, solar, and EV-related aluminum components rather than construction profiles, which aligns directly with inverter enclosure needs.

Understanding Tolerances for CNC Machining for Inverter Enclosures

Machining tolerances may seem like a dry topic, but they determine whether your inverter seals correctly, resists vibration, and survives outdoor life.

Critical Tolerances for Inverter Housing

In 2025, industrial buyers typically request:

- ±0.02 mm on sealing surfaces

- ±0.05 mm on non-critical surfaces

- 0.01 mm flatness tolerance on lid interfaces

- Precise perpendicularity for PCB mounting bosses

These ensure:

- No leaks

- No misalignment

- Stable PCB positioning

- Reduced vibration failures

When sourcing in Vietnam, KIMSEN’s CMM (Coordinate Measuring Machine) inspection is a major advantage because many smaller workshops still rely on manual gauges.

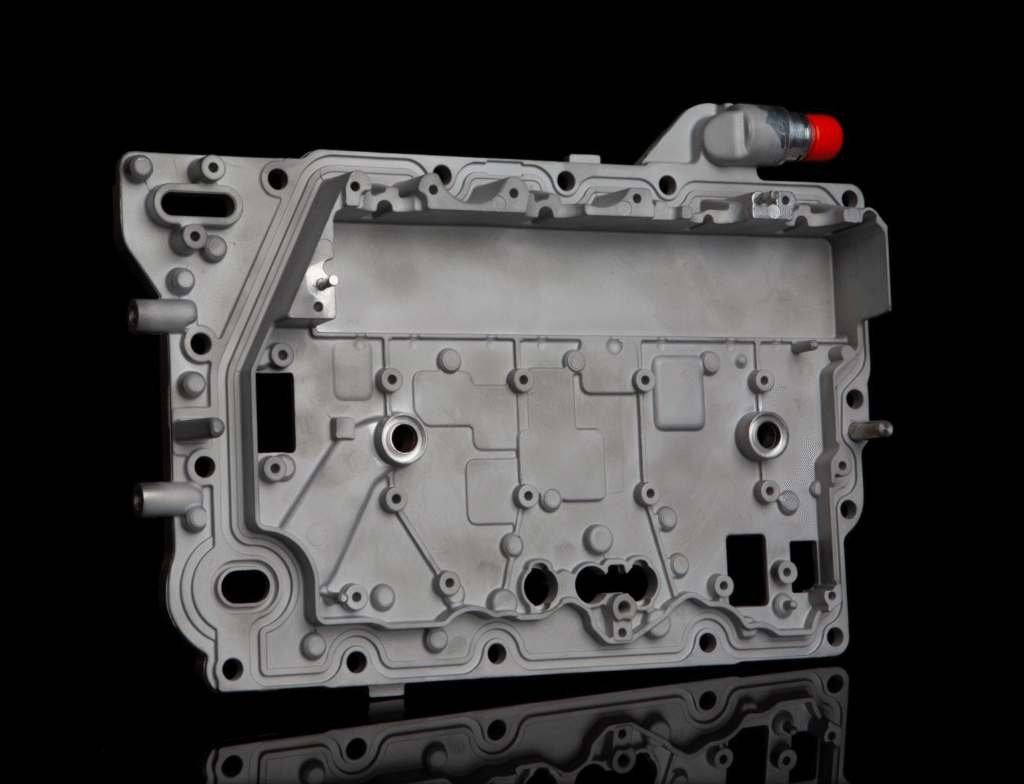

Surface Finishes That Improve Performance and Durability

For inverter housing, machining is just step one. The surface finish determines corrosion resistance, insulation behavior, and heat transfer.

Most Common 2025 Finishes

- Anodizing (clear or black) — corrosion protection + heat dissipation

- Powder coating — UV resistance for outdoor inverters

- Sandblasted anodizing — premium aesthetic and uniform texture

- Chromate conversion — electrical conductivity where needed

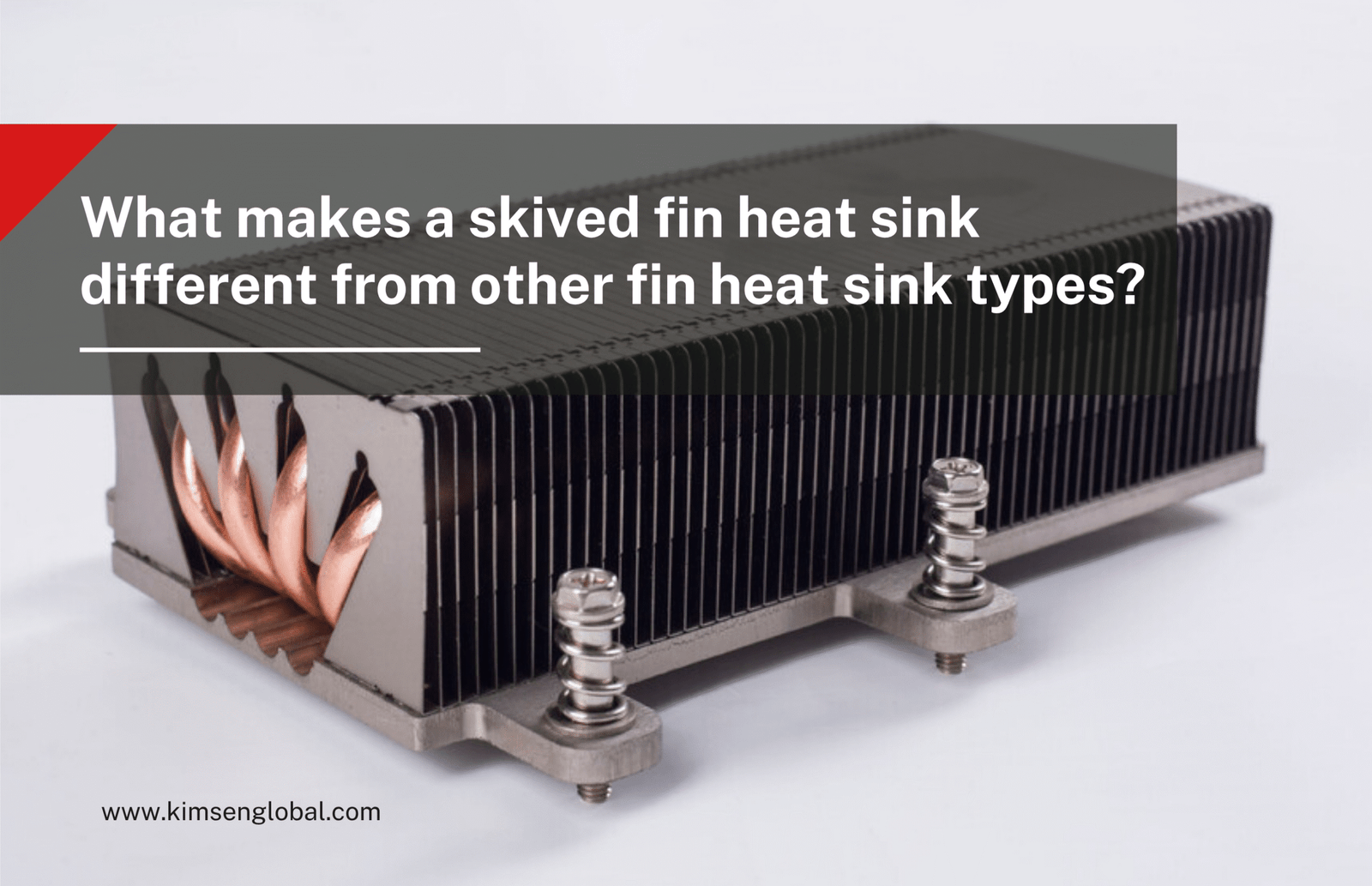

How Finishes Affect Real Performance

The finish isn’t just cosmetic. It directly affects:

- Heat performance: darker anodized finishes radiate heat more efficiently

- Outdoor lifespan: powder coating withstands UV, salt fog, and humidity

- Safety: coatings can add dielectric layers for isolation

US and EU customers—especially in solar and industrial automation—often request multi-stage finishing, and KIMSEN’s in-house finishing line helps reduce total cycle time.

Design Guidelines for Better CNC Machined Inverter Housing

A smart design strategy cuts machining time, reduces scrap, and improves assembly.

Key Design Tips

1. Avoid overly thin walls

Aim for 2.0–2.5 mm minimum for aluminum housings. Anything thinner risks warping.

2. Use fillets instead of sharp corners

Since milling tools are round, internal sharp corners slow down machining or require extra passes.

3. Plan for heat

Integrate internal or external fins directly into the housing body when possible. CNC machining supports deep, precise fin structures for better cooling.

4. Remember post-processing requirements

Coating thickness adds roughly 10–25 μm depending on the finish—important for gasket grooves or sliding assemblies.

Cost Structure for CNC Machined Inverter Housing (2025 Pricing Trends)

After global shipping price fluctuations in late 2024, buyers entering 2025 focus heavily on predictable costing.

Main Cost Drivers

1. Material (20–30%)

Aluminum prices have stabilized somewhat in Q1 2025, but remain higher than pre-2022 levels.

2. Machining Time (40–50%)

Complex interior pockets or deep slots increase machine cycle times significantly.

3. Finishing (10–20%)

Anodizing is cost-effective; powder coating tends to be more expensive.

4. Quality Control & Testing (5–10%)

CMM, salt spray testing, and dimensional reports add to the cost but are often required for EU/US compliance.

Why Vietnam Offers Better Value

Vietnam, particularly suppliers like KIMSEN, provides:

- Lower machining labor cost

- Faster lead times than China

- Stability despite ongoing tariffs

This combination makes Vietnam an ideal sourcing destination in 2025.

Sourcing CNC Machined Inverter Housing from Vietnam in 2025

US and EU customers increasingly choose Vietnam for stability and quality.

Why KIMSEN Industrial Corporation Stands Out

- Strong aluminum extrusion + CNC capabilities

- ISO 9001, ISO 14001, and IATF-certified workflows

- Modern Japanese and European machining centers

- In-house anodizing and powder-coating

- Technical engineers who review DFM suggestions

- Proven experience with power electronics components

With geopolitical uncertainties still shaping global supply patterns, Vietnam—and KIMSEN in particular—offers a more reliable long-term sourcing choice.

Quick Takeaways

- A well-designed inverter housing improves thermal performance, sealing, and durability.

- CNC machining offers top accuracy for 2025’s increasingly compact inverter designs.

- Aluminum remains the best choice for weight, thermal conductivity, and corrosion resistance.

- KIMSEN Industrial Corporation is a leading Vietnamese supplier for CNC machined inverter enclosures.

- Global trade shifts in 2025 make Vietnam an attractive and stable sourcing option.

- Surface finish choices—especially anodizing—impact both aesthetics and performance.

- Clear tolerance requirements reduce delays and improve consistency across batches.

Conclusion

The inverter housing you choose—its design, machining quality, and surface treatment—directly impacts the reliability of your EV, solar, or industrial power system. As hardware becomes more compact and heat loads rise, accuracy and durability matter more than ever. That’s why CNC machining remains the preferred method and why many US and EU companies are shifting production to Vietnam, where suppliers like KIMSEN Industrial Corporation combine reliable engineering, competitive pricing, and export-ready quality standards.

Read more: Inverter Housing Thermal Design with Heatsinks & Ventilation – KIMSEN Industrial Corporation