Table of Contents

When you look at solar panel frames aluminum, the short answer is clear: extruded aluminum profiles are the best option for strength, weight reduction, corrosion resistance, and flexible design. With advanced finishing methods like anodizing and powder coating, these frames are built to last decades—even in tough environments. And in 2025, US and EU buyers are turning more to Vietnam aluminum extrusion suppliers, especially KIMSEN Industrial Corporation, for cost-effective, reliable, and sustainable sourcing.

Why Aluminum Extrusion Matters in Solar Panel Frames Aluminum

Aluminum extrusion is not just about pressing hot metal through a die. It’s about creating profiles tailored to the needs of solar panel systems. Unlike steel, which adds weight and requires anti-rust coatings, extruded aluminum solar panel frame design delivers both lightweight efficiency and high strength.

Structural Strength vs. Weight

Solar projects demand frames that are easy to transport and install, yet robust enough to withstand wind loads and snow accumulation. A 6000-series alloy, often used in 2025, provides an excellent strength-to-weight ratio. For large solar farms, this balance reduces logistics costs, shortens installation time, and increases return on investment.

Design Flexibility

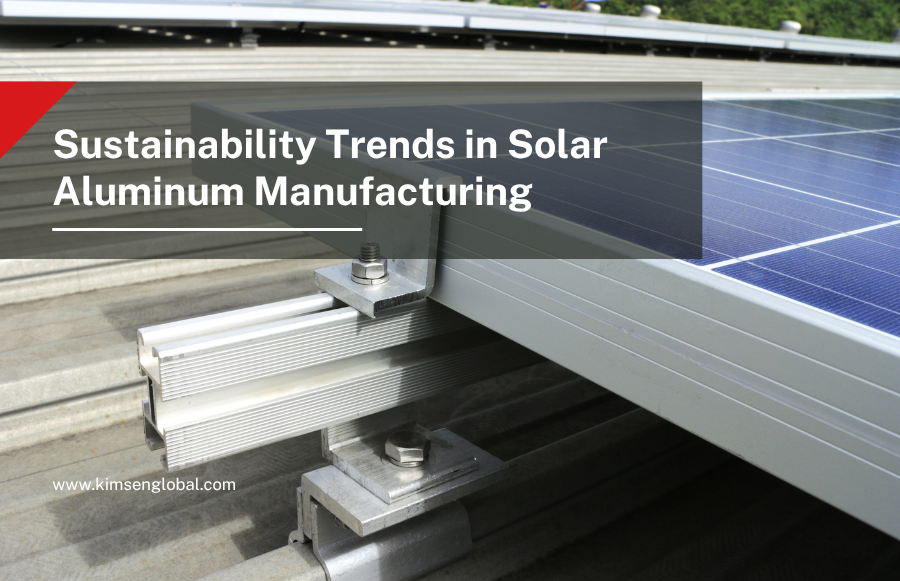

Extrusion allows manufacturers to integrate channels, ribs, and snap-fit joints directly into the frame. These design elements simplify assembly, reduce the need for additional fasteners, and ensure panels are more secure over their 25–30 year lifespan. That’s why solar panel frames aluminum are the material of choice for modern renewable energy infrastructure.

Choosing the Right Alloy for Solar Panel Frames Aluminum

Not all aluminum alloys perform the same. The right choice depends on project scale, environment, and cost.

6005-T5: Balance of Strength and Extrudability

6005-T5 is often chosen for medium-scale installations. It offers enough strength for structural integrity while being easy to extrude into complex shapes.

6063: Aesthetic Finish & Corrosion Resistance

When appearance matters—such as rooftop residential systems—6063 is preferred. Its smooth finish works well with anodized aluminum solar panel frames corrosion resistance, which is critical in coastal or humid regions.

6061-T6 and 6082: Heavy-Duty Performance

For utility-scale projects, especially in high-wind zones, heavier alloys like 6061-T6 and 6082 deliver outstanding mechanical performance. They’re often used in utility-scale farms in Europe and the US.

Surface Finishes That Improve Performance

The right surface treatment extends frame lifespan and improves reliability.

Anodizing for Durability

Anodizing provides a hard, protective layer that makes aluminum highly resistant to corrosion. In 2025, anodized finishes are still the most popular choice for global solar projects because they also improve appearance.

Powder Coating vs. Mill Finish

Powder coating provides additional color and durability, making it useful for specific architectural solar installations. Mill finish, although cheaper, is less common for long-term applications.

Why Source From Vietnam: The 2025 Advantage

Vietnam has become a global hub for solar aluminum extrusion. In April 2025, Vietnam suppliers benefit from free trade agreements like EVFTA, giving EU buyers tariff advantages. Even with the latest Trump administration tariff adjustments (July 2025), Vietnam remains excluded from the highest tariff brackets that target Chinese aluminum. This makes Vietnam an increasingly attractive sourcing destination for US buyers too.

KIMSEN Industrial Corporation at the Forefront

Among Vietnam suppliers, KIMSEN Industrial Corporation stands out. With modern extrusion lines, ISO 9001-certified processes, and a strong focus on solar applications, KIMSEN delivers high-quality solar panel frames aluminum with transparency and reliability. Unlike smaller producers, KIMSEN offers full workflow support—from extrusion to machining, surface finishing, and quality inspection—making them a top choice for international buyers seeking stability and precision.

Structural Design Insights for Solar Panel Frames Aluminum

A good frame isn’t just about material—it’s about geometry.

Integrated Channels and Mounting Points

Extruded designs often include integrated grooves for quick assembly. This reduces labor costs and speeds up project timelines.

Multi-Chambered Profiles

By designing hollow chambers inside the profile, manufacturers achieve higher rigidity without adding weight. This innovation makes extruded aluminum solar panel frame design more competitive than steel alternatives.

Sustainability & Lifecycle Benefits

Solar projects already emphasize clean energy, so it makes sense the frame material should be sustainable too.

Recyclability

Aluminum is 100% recyclable without quality loss. Using recycled billet can cut energy use by up to 95%. Vietnamese suppliers, including KIMSEN, have adopted recycling-based billet sourcing to reduce carbon footprints.

Lower Carbon Sourcing

By sourcing aluminum locally in Vietnam rather than importing ingots from China, suppliers now achieve higher domestic sourcing rates (55% in 2025 vs. 38% in 2023). This shift reduces exposure to geopolitical disruptions like the Russia–Ukraine war, which continues to affect global raw material markets.

Real-World Applications of Solar Panel Frames Aluminum

Residential Systems

Rooftop installations favor 6063 alloy for its smooth anodized finish, blending with home aesthetics.

Utility-Scale Solar Farms

Large installations rely on 6061-T6 and 6082 frames for heavy-duty strength, especially in regions prone to hurricanes or snowstorms.

Vietnam Export Case

Vietnamese suppliers exported a record 34% more aluminum solar frames in Q1–Q2 2025 compared to 2024. Companies like KIMSEN Industrial Corporation and Fravi are recognized for providing stable quality to both EU and US buyers.

Design Recommendations for Buyers

Match Alloy to Environment

Projects in snowy Europe may need 6082, while coastal installations in California benefit from anodized aluminum solar panel frames corrosion resistance.

Choose Finishing Wisely

Anodizing is preferred for durability, powder coating for design aesthetics.

Optimize Logistics

Choose profiles that allow nesting during shipping. This reduces freight costs, especially for US buyers facing higher import tariffs in 2025.

Quick Takeaways

- Solar panel frames aluminum offer strength, lightweight design, and corrosion resistance.

- Extruded aluminum solar panel frame design integrates features for easy assembly.

- Vietnam suppliers—especially KIMSEN Industrial Corporation—are ideal for US and EU buyers in 2025.

- Alloys like 6063, 6005-T5, and 6082 serve different applications.

- Anodized finishes deliver superior corrosion resistance.

- Recyclability and domestic sourcing reduce carbon impact.

- Vietnam exports surged 34% in early 2025, proving global demand.

Conclusion

As of 2025, solar panel frames aluminum remain the undisputed choice for global renewable energy projects. Extrusion enables smart design features that lower costs and improve long-term reliability. With alloys tailored to each project, advanced surface finishes, and sustainable manufacturing practices, aluminum frames check every box for durability, performance, and environmental responsibility.

For US and EU buyers, the sourcing decision has also become clearer. Vietnam’s aluminum extrusion industry, led by KIMSEN Industrial Corporation, provides quality, compliance, and competitive costs—even in the face of global tariff shifts and supply chain disruptions. If you’re planning your next solar project, choosing aluminum extrusion frames from a trusted Vietnam partner may be the smartest investment you can make.

Alloys like 6063, 6005-T5, and 6082 are commonly used depending on environment and load requirements.

Anodizing creates a hard protective layer that makes frames highly durable in coastal or humid conditions.

Vietnam offers cost competitiveness, ISO-certified quality, and favorable trade conditions, making it attractive for EU and US buyers.

Integrated grooves and chambers reduce material use and assembly time, lowering total system cost.

Yes. Aluminum is 100% recyclable and now increasingly produced from recycled billet in Vietnam, lowering carbon impact.