An aluminum heat sink extrusion creates lightweight, cost-effective thermal solutions with excellent conductivity—making it the go-to cooling method in electronics, EVs, and industrial applications. With rising thermal demands in 2025 and supply chain pressures from tariffs and geopolitical shifts, many US and EU buyers are turning to Vietnamese manufacturers like KIMSEN Industrial Corporation for quality and stability. This article explores the full extrusion process, from billet to finished heatsink, highlighting design tips, alloy selection, post-processing, and real-world sourcing insights.

What Is Aluminum Heat Sink Extrusion?

A Simple Process for Aluminum Heat Dissipation Design

Aluminum heat sink extrusion involves forcing heated aluminum billets through a die to form long, finned profiles used to dissipate heat. It’s a proven method for creating consistent, high-volume, cost-efficient extruded aluminum cooling solutions.

Why Extruded Aluminum Cooling Outperforms Other Heatsink Methods

Compared to die casting or CNC machining, extrusion offers:

-

- Greater design flexibility (variable fin shapes, lengths)

-

- Lower cost per unit in medium-to-high volumes

-

- Better thermal conductivity, especially using 6000-series alloys

>> Read more: Why Extruded Aluminum Heatsinks Dominate Cooling?

Step-by-Step Overview of the Extrusion Process

Billet Preparation in Thermal Aluminum Extrusion

Aluminum billets are heated to around 900°F (482°C) to soften the metal. The billet must be uniform and free of inclusions to ensure smooth flow during extrusion.

Die Design for Heatsink Profiles and Complex Fins

The billet is pushed through a custom die using hydraulic pressure. The shape of the die determines the final aluminum heatsink profile, including fin count, pitch, and base width.

Cooling and Quenching in Custom Heatsink Extrusion

As the extruded profile exits the die, it’s rapidly cooled with water or air to lock in mechanical properties. The profiles are then straightened, cut to length, and aged to reach T5 or T6 hardness.

Material Choices: Why 6000-Series Alloys Dominate

Choosing the Right Alloy for Efficient Aluminum Heat Transfer

Most aluminum heat sink extrusions use:

-

- 6063: Excellent surface finish, great for anodizing, decent conductivity

-

- 6061: Stronger, more machinable, slightly lower conductivity

Balancing Conductivity and Strength in Heatsink Materials

While 1050 aluminum has slightly higher conductivity, it lacks the strength and extrudability of 6000-series alloys. That’s why 6063 remains the industry standard for extruded aluminum cooling in power electronics and computing.

Key Design Factors That Affect Thermal Performance

Fin Geometry and Spacing in Extruded Aluminum Cooling Profiles

More fins don’t always mean better cooling. Factors like:

-

- Fin spacing (narrow for natural convection, wider for forced air)

-

- Height-to-thickness ratio (avoid buckling during extrusion)

-

- Orientation (horizontal vs. vertical)

…all affect airflow and heat dissipation efficiency.

Base Thickness and Contact in Heatsink Extrusions

A thicker base stores and spreads heat better, especially under power transistors or MOSFETs. But too thick adds weight and material cost.

Designing for Efficient Thermal Aluminum Extrusion

Consider:

-

- Uniform wall thickness

-

- Tapered ends for easy die flow

-

- Avoiding undercuts (unless post-machined)

These choices reduce tooling cost, scrap, and lead time.

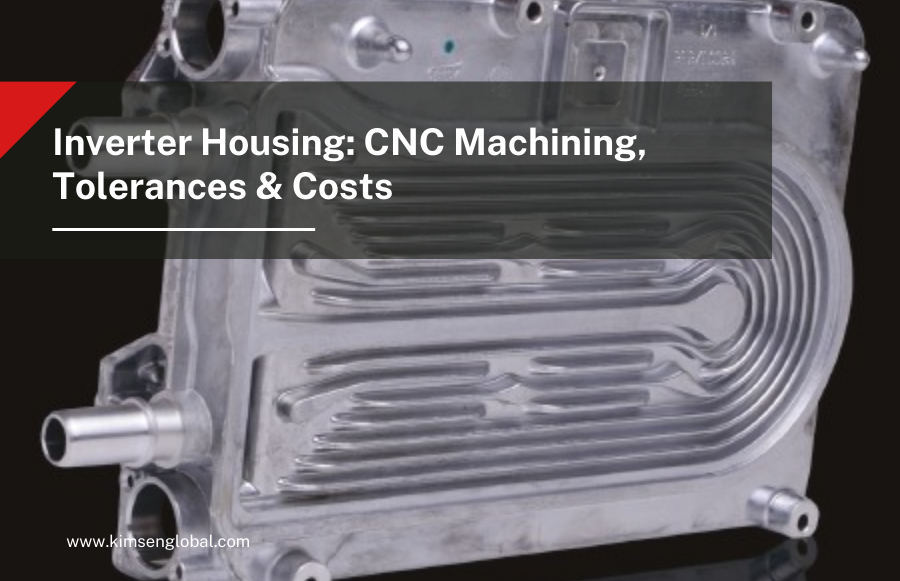

Secondary Operations After Aluminum Extrusion

CNC Machining and Post-Processing for Heatsinks

Extruded heatsinks often require post-processing:

-

- Drilling, tapping for component attachment

-

- Surface flatness milling for TIM (thermal interface material)

-

- Chamfers or grooves for assembly

Surface Finishing to Enhance Aluminum Heat Dissipation

Anodizing isn’t just aesthetic. It:

-

- Improves corrosion resistance

-

- Enhances emissivity (especially black anodizing)

-

- Offers electrical insulation in some applications

Adding Hardware to Complete the Custom Heatsink

Features like threaded inserts, standoffs, or PEM nuts can be added for turnkey thermal module assembly—saving you time and integration effort.

Vietnam’s Edge in Aluminum Heatsink Manufacturing

Lower Costs and Trade Advantages for Extruded Cooling Profiles

With US–China tariffs still at 25% in July 2025 and ongoing disruption from the Ukraine conflict affecting EU trade lanes, Vietnam’s aluminum sector has become the alternative sourcing hub for many OEMs and tier-1 buyers.

Why KIMSEN Leads in Thermal Aluminum Extrusion in Vietnam

KIMSEN Industrial Corporation delivers:

-

- Fully integrated production: Extrusion + CNC + finishing + assembly

-

- Certifications: ISO 9001, ISO 14001, IATF 16949

-

- Experience: Serving automotive, telecom, and renewable energy clients

-

- Support: Fluent English-speaking engineers and fast prototype timelines

In 2025, KIMSEN is not just another Vietnamese supplier—they’re a strategic manufacturing partner.

Sourcing Aluminum Heat Sink Extrusion in 2025

Vietnam offers a reliable, tariff-free route for EU and US buyers seeking high-quality aluminum heat sink extrusion with fast turnaround and lower costs.

Applications for Aluminum Heat Sink Extrusion in 2025

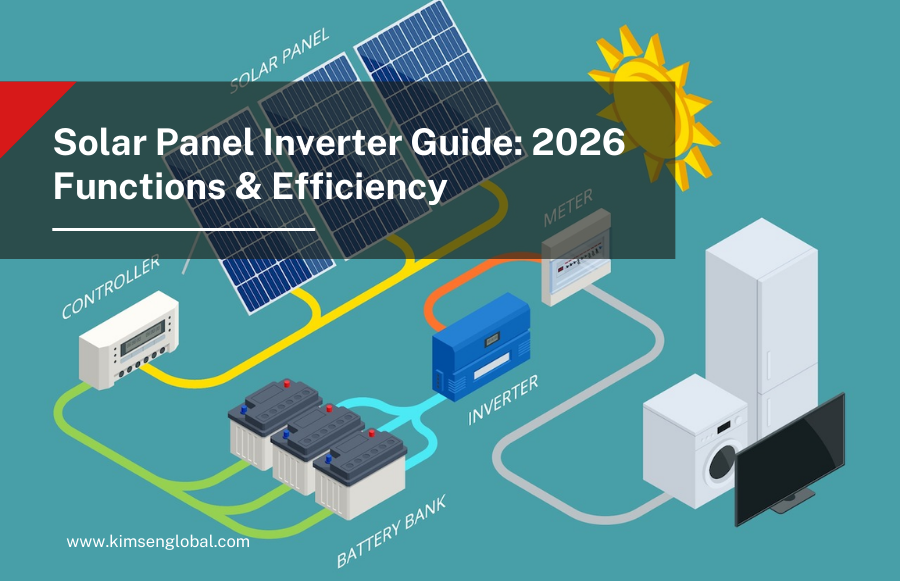

Using Extruded Heatsinks in EVs and Charging Stations

From inverter modules to DC-DC converters, extruded aluminum cooling is essential to maintain component lifespan and thermal safety margins.

Heatsink Profiles for Servers, Telecom, and Computing

Think GPU coolers, power regulator heatsinks, SSD cases—many feature aluminum heat sink extrusion profiles for airflow efficiency and weight savings.

Industrial Drives and Solar Inverter Cooling Systems

These environments demand:

-

- High durability

-

- Fast thermal response

-

- Compact form factors

…which extruded profiles can deliver with minimal machining.

Performance Testing and Heatsink Quality Validation

Measuring Thermal Resistance in Custom Heatsink Profiles

Manufacturers test the °C/W rating under airflow conditions to validate real-world performance. A typical medium-size heatsink may offer 0.9–1.5°C/W under forced air.

Verifying Straightness and Dimensions in Extruded Aluminum Cooling

Tolerance is key—especially when mounting to PCBs or aligning with enclosures. KIMSEN uses automated vision and laser-based inspection tools to ensure each heatsink meets spec.

Surface Testing for Coating and Corrosion Resistance

Final QA checks include salt-spray testing (ASTM B117) for anodized layers and tape pull tests for surface adhesion.

What’s New in Heatsink Extrusion Technologies?

Advanced Extrusion and 3D-Enhanced Aluminum Cooling

In 2025, 3D printing enables more intricate geometries—especially useful in tight electronics packaging.

Hybrid Systems with Heat Pipes and Extruded Profiles

Some OEMs are bonding extruded heatsinks with vapor chambers or embedding heat pipes to maximize efficiency without changing form factor.

Quick Takeaways

-

- The aluminum heat sink extrusion process enables scalable, precise, and cost-effective thermal solutions.

-

- 6000-series alloys strike a great balance between conductivity and machinability.

-

- Vietnam, led by KIMSEN, is a strategic sourcing location for US and EU buyers in 2025.

-

- Extruded aluminum cooling profiles support a wide range of sectors—from EVs to solar.

-

- Post-processing and design play a huge role in performance and cost-efficiency.

Frequently Asked Questions

1. Why is aluminum used for heatsinks?

Aluminum offers excellent thermal conductivity, low weight, corrosion resistance, and is easily extruded into complex shapes.

2. What’s the typical lead time for a custom aluminum heatsink extrusion?

4–6 weeks depending on tooling, complexity, and post-processing requirements.

3. Can extruded heatsinks be used outdoors?

Yes—with anodizing or powder coating, they’re corrosion-resistant and UV-stable.

4. Is KIMSEN able to support low-volume orders?

Absolutely. KIMSEN offers both prototype support and mass production for global clients.

5. How do I calculate heatsink performance?

Use thermal resistance (°C/W), surface area, and airflow data—manufacturers like KIMSEN can assist with simulation or thermal testing.

Conclusion: Partner Smarter, Cool Better

The aluminum heat sink extrusion process is more than just shaping metal—it’s engineering thermal performance at scale. From choosing the right alloy and die design to partnering with a manufacturer who understands your market and timeline, every decision impacts your product’s reliability and cost structure.

In today’s complex trade climate and competitive product cycles, companies like KIMSEN Industrial Corporation in Vietnam offer a rare combination: world-class capability, responsive communication, and tariff-safe logistics. Whether you’re sourcing your first heatsink or upgrading to a lighter, more efficient solution, now’s the time to look into precision-extruded profiles tailored to your application.

What’s Your Next Project?

Have you used extruded aluminum cooling solutions before? What design or sourcing challenge are you tackling this year? Drop your feedback, or share this guide with your engineering or procurement team to start the conversation.

FAQs

Aluminum offers excellent thermal conductivity, low weight, corrosion resistance, and is easily extruded into complex shapes.

4–6 weeks depending on tooling, complexity, and post-processing requirements.

Yes—with anodizing or powder coating, they’re corrosion-resistant and UV-stable

Absolutely. KIMSEN offers both prototype support and mass production for global clients.

Use thermal resistance (°C/W), surface area, and airflow data—manufacturers like KIMSEN can assist with simulation or thermal testing.