Global solar aluminum manufacturing trends in 2025 point toward a new era of reshored production, recycled content, tariff-driven sourcing shifts, and a rising Southeast Asian footprint—especially Vietnam. With demand soaring across the US and EU, and mounting policy pressures from both the Biden-era tariffs and the lingering economic effects of the Ukraine-Russia conflict, buyers are turning to agile, low-carbon suppliers. And in this reshaped landscape, KIMSEN Industrial Corporation stands at the forefront as Vietnam’s trusted source for high-quality solar aluminum extrusion components.

Global Supply Chain Shifts in Solar Aluminum Manufacturing Trends

Chinese dominance in solar aluminum manufacturing trends is plateauing

China has historically dominated the aluminum industry solar chain, producing over 80% of global solar PV components as of 2024. However, by mid-2025, signs of consolidation, regulatory caps on energy-intensive smelters, and geopolitical friction with the US and EU have led to sourcing diversification.

Southeast Asia’s extrusion market PV growth in solar aluminum supply

Vietnam, Malaysia, and Thailand are now leading a Southeast Asian surge. Vietnam in particular has become a critical hub for solar racking exports. Lower labor costs, trade agreements like EVFTA, and a proven record of aluminum extrusion quality have made it a favorite among US and EU procurement managers.

Forecast for Global Solar Aluminum Industry Growth

Solar aluminum frame market trends project growth to 2030

According to ResearchAndMarkets (June 2025), the global aluminum frame market for solar is expected to grow from USD 15 billion in 2024 to over USD 30 billion by 2030. Much of this growth will come from:

- Utility-scale solar farm expansions

- Residential rooftop growth in Europe and North America

- Supportive policy packages (e.g. EU’s Green Deal, US IRA extension)

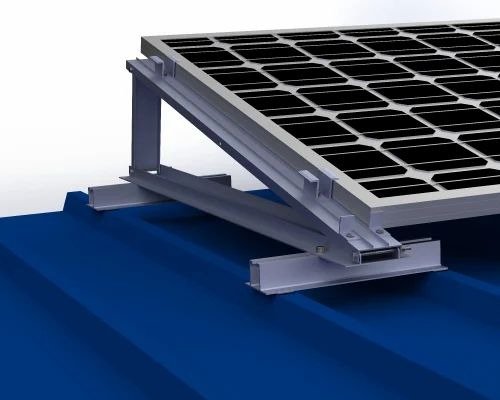

Renewable energy and extrusion market PV demand are key drivers

With solar installations expanding into harsher climates, the demand for corrosion-resistant, high-strength aluminum frames is climbing. The extrusion market PV segment is evolving with thinner-wall, high-tolerance profiles engineered for wind, snow, and seismic zones.

Sustainability Trends in Solar Aluminum Manufacturing

Recycled aluminum and green smelting in solar frame production

From Norsk Hydro’s low-carbon billet initiatives to China’s cap on energy-intensive aluminum plants, sustainability is now a competitive differentiator. Solar buyers increasingly demand Environmental Product Declarations (EPDs) and traceable recycled content.

Global and regional solar aluminum sustainability programs

- UAE’s Emirates Global Aluminium launched “CelestiAL” solar aluminum (2024), smelted using 100% renewable energy

- China is rapidly expanding green alumina refining projects

- EU is moving toward Scope 3 carbon disclosure standards by late 2025

Tariff & Trade Factors in Solar Aluminum Manufacturing Trends

US tariffs reshaping global solar aluminum sourcing trends

Ongoing tariffs (Section 301, extended in 2025 by the new US administration) continue to penalize Chinese solar aluminum. The result? US buyers are actively shifting to tariff-exempt countries like Vietnam.

Ukraine-Russia war impact on solar aluminum extrusion market PV in EU

EU supply chains remain sensitive to war-related logistics disruptions and rising aluminum ingot prices. In response, European solar frame buyers have increasingly looked to Vietnam’s aluminum extrusion sector for cost-stable contracts.

Vietnam’s Role in Global Solar Aluminum Manufacturing Trends

Vietnam solar aluminum exports rise amid global sourcing shifts

Vietnam’s aluminum industry solar exports grew by over 20% in H1 2025. Factors driving growth include:

- EVFTA tariff elimination for EU buyers

- Regional shipping agility (compared to inland China)

- Reliability in extrusion precision and anodized finish quality

KIMSEN leads Vietnam’s extrusion market PV supply chain

As one of Vietnam’s premier aluminum extruders, KIMSEN Industrial Corporation leads with:

- High-strength 6005-T5 and 6063 solar aluminum profiles

- Precision CNC capabilities and tight-tolerance fabrication

- Export-ready packaging and compliance with US/EU solar standards

- Capacity to handle large PV contracts and custom racking profiles

>> Read more: Top Aluminum Alloy for Solar Mounting Systems

Technology & Innovation in Solar Aluminum Manufacturing Trends

PV extrusion market investing in precision solar aluminum

The shift from bulk to precision means suppliers are investing in:

- Dies capable of producing ultra-thin walls (<1.8 mm)

- Automated straightness inspection

- Hard anodizing for marine or coastal installations

Solar aluminum anodizing and profile design innovations

Profiles are now engineered with built-in drainage, module clips, and grounding slots. The anodizing process is optimized to enhance UV protection and durability, especially in black and matte silver finishes.

Resilience and Risk in Global Solar Aluminum Trends

China slowdown opens global solar aluminum capacity

With overcapacity concerns in China’s extrusion market PV sector, smaller ASEAN markets can absorb volume with more stable pricing. In 2025, this also means less exposure to geopolitical shocks.

Vietnam’s reliable labor force boosts solar aluminum stability

Vietnam’s younger industrial workforce, supported by rising technical training initiatives, ensures long-term production stability. Power reliability has also improved, lowering operational risks versus older Chinese grids.

Sourcing Strategy for Solar Aluminum Buyers in 2025

Best practices for navigating solar aluminum manufacturing trends

- Ask for mill certificates, EPDs, and RoHS declarations

- Choose suppliers with in-house finishing to cut delays

- Negotiate FOB terms from Vietnamese ports (Hai Phong, Cat Lai)

Why solar aluminum manufacturing trends favor Vietnam sourcing

The combination of price stability, lower risk of sanctions, and rising green credentials make Vietnam—and KIMSEN—the strategic answer for solar buyers caught between ESG mandates and cost control.

Quick Takeaways: Global Solar Aluminum Manufacturing Trends

- Global demand for solar-grade aluminum is surging toward USD 30B by 2030

- China’s dominance is softening due to energy limits and tariffs

- Vietnam is emerging as a strategic solar aluminum hub

- Sustainability is no longer optional—EPDs and recycled content are must-haves

- Trade policies and war disruptions make diversified sourcing a necessity

Conclusion: Vietnam & KIMSEN Lead Solar Aluminum Manufacturing Trends

As the global solar industry races toward climate targets, the pressure is on to deliver durable, sustainable, and tariff-resilient aluminum solutions. The solar aluminum manufacturing trends of 2025 reflect a clear pivot from Chinese centralization to a more diversified, Southeast Asia–led supply chain. Vietnam, and particularly KIMSEN Industrial Corporation, now offer the performance, transparency, and cost control global buyers demand.

Smart sourcing in 2025 means planning for resilience. Whether you’re sourcing solar racking for rooftop arrays in Spain or utility fields in Arizona, choosing a partner like KIMSEN can unlock speed, quality, and long-term value.

FAQs

They include sourcing diversification from China to Vietnam, increased use of recycled aluminum, tariff-driven supplier shifts, and demand for anodized, high-tolerance profiles.

Vietnam combines low costs, trade benefits, export readiness, and skilled extrusion capabilities, making it ideal for US and EU solar buyers.

Tariffs on Chinese goods (Section 301 and EU duties) have driven buyers to look toward ASEAN producers like Vietnam for reliable, tariff-free options.

KIMSEN is a leading Vietnamese manufacturer providing custom extruded aluminum frames and solar mounting components with certified quality and export packaging.

Look for ISO 9001, EPD, RoHS, anodizing spec sheets, and test reports validating alloy temper and surface resistance.