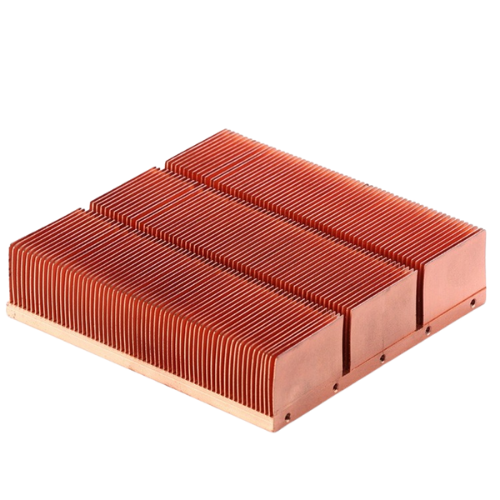

Skived Fin Heat Sinks by KIMSEN

Designed for applications with high power density, KIMSEN’s Skived Fin Heat Sinks offer efficient thermal performance in compact spaces. With high-density fins formed from a single block of material, these heat sinks maximize surface area, providing outstanding cooling capabilities where space is limited.

Specification

Product Details

specification

Tailored Solutions

Custom fin designs for unique needs.

- Technology

- Advance Manufacturing

- Materials

- KIMSEN’s Expertise

Our Skived Fin Heat Sinks utilize a specialized manufacturing process that forms fins directly from a solid block, creating a seamless connection between base and fins. This method not only increases structural integrity but also enhances heat transfer efficiency, making it suitable for applications where compact, robust cooling solutions are required.

High-Density Fin Structure for Optimal Heat Dissipation

The skiving process enables KIMSEN to achieve a high fin density that maximizes surface area, allowing more heat to disperse rapidly. This is especially valuable for equipment with limited space, where traditional heat sink designs may be less effective. By increasing the contact area, our Skived Fin Heat Sinks ensure efficient heat transfer even in high-power applications.

KIMSEN’s Skived Fin Heat Sinks are available in high-grade aluminum or copper, depending on the specific. cooling and durability needs. Our team can customize the fin density, height, and thickness based on your requirements, ensuring optimal performance in challenging environments.

KIMSEN brings years of expertise to the design and manufacture of thermal solutions, and our Skived Fin Heat Sinks are no exception. We understand the demands of high-power devices and industries, delivering reliable, high-performance products built to last.