Heatpipe Assembly by KIMSEN

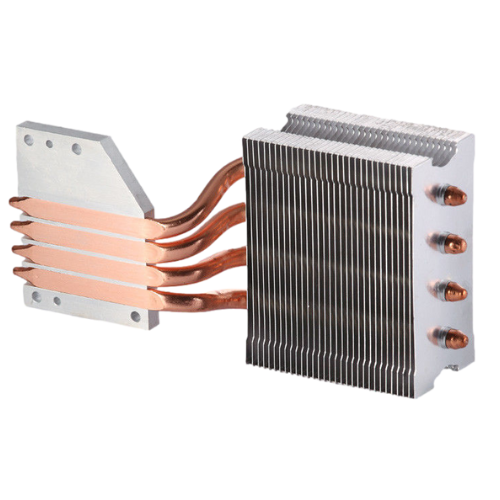

At KIMSEN Industrial Corporation, we specialize in manufacturing high-performance thermal solutions designed to meet the rigorous demands of modern industries. Our Heatpipe Assembly is a prime example of our advanced capabilities, leveraging cutting-edge technology and superior materials to provide efficient thermal management across a wide range of applications.

Specification

Product Details

specification

Custom Precision Engineering

Tailored heatpipe assemblies with exact tolerances for specific applications.

Advanced Thermal Technology

Efficient heat transfer through cutting-edge phase-change technology.

High-Quality Materials

Premium copper and aluminum construction for superior conductivity and durability.

- Technology

- Precision Manufacturing

- Materials

- Methodologies

- KIMSEN’s Expertise

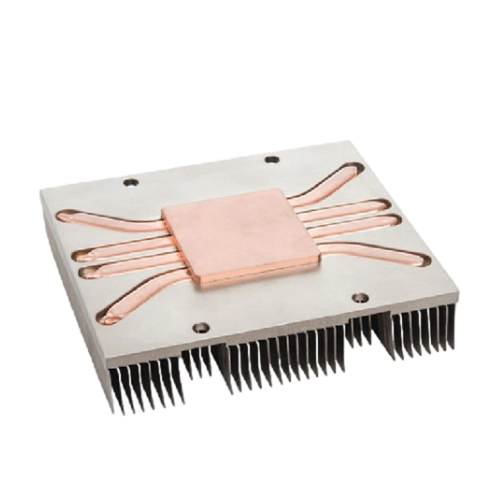

The core of our Heatpipe Assembly lies in the innovative use of heatpipe technology. A heatpipe is a thermal superconductor that efficiently transfers heat from a heat source to a cooling area. The mechanism relies on phase change—where liquid inside the pipe evaporates at the hot end, absorbs heat, and transports it as vapor to the cooler end, where it condenses back into liquid, releasing heat in the process. This cyclical phase transition enables rapid and highly efficient heat transfer with minimal thermal resistance.

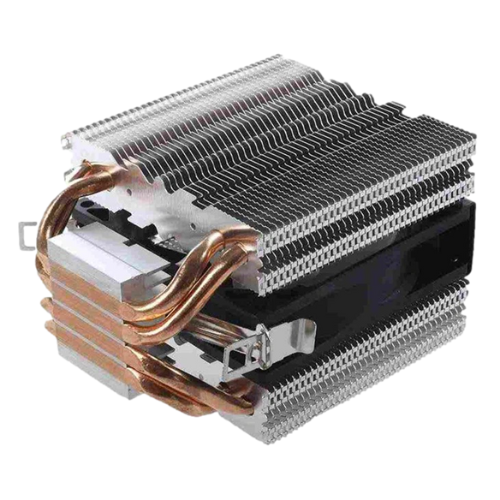

With a focus on precision engineering, KIMSEN manufactures heatpipes with exacting standards. Our advanced CNC machining capabilities ensure that every component of the assembly meets tight tolerances, resulting in reliable performance and durability.

We also offer customized Heatpipe Assembly solutions tailored to your specific requirements. Whether it’s a bespoke shape, size, or material, we can create a thermal solution that integrates seamlessly with your product design while maximizing cooling efficiency.

At KIMSEN, material selection is paramount to ensuring the performance and longevity of our Heatpipe Assemblies. We use high-grade aluminum, known for its exceptional thermal conductivity and durability, along with other materials like copper for lightweight applications or stainless steel for enhanced corrosion resistance.

Our manufacturing processes include precision forming, brazing, and sealing, ensuring that each assembly is airtight and highly efficient in conducting heat. This combination of premium materials and refined production techniques results in a robust solution capable of withstanding extreme temperatures and harsh operational environments.

Our approach to thermal management goes beyond standard practices. KIMSEN’s R&D team is constantly exploring new methodologies to enhance the efficiency of our Heatpipe Assemblies. Whether through optimizing the internal wicking structure of the heatpipes for improved fluid return or refining the heat exchanger design, we aim to provide solutions that push the boundaries of thermal performance.

By working closely with our clients, we ensure that our heatpipe solutions are not only efficient but also aligned with their specific cooling requirements, helping them achieve better operational efficiency, product longevity, and overall cost savings.

KIMSEN Industrial Corporation has built a solid reputation for its capability to manufacture high-performance thermal products, including Heatpipe Assemblies. Our vertically integrated production process allows us to control every stage of manufacturing, from material selection to final quality control, ensuring consistent and reliable output.

We serve a variety of industries, including electronics, telecommunications, automotive, and industrial equipment, offering tailored thermal management solutions that meet the unique needs of each sector. Our commitment to innovation, precision, and quality is what sets us apart in the field of thermal technology.