Aluminum Extrusion Heat Sinks by KIMSEN

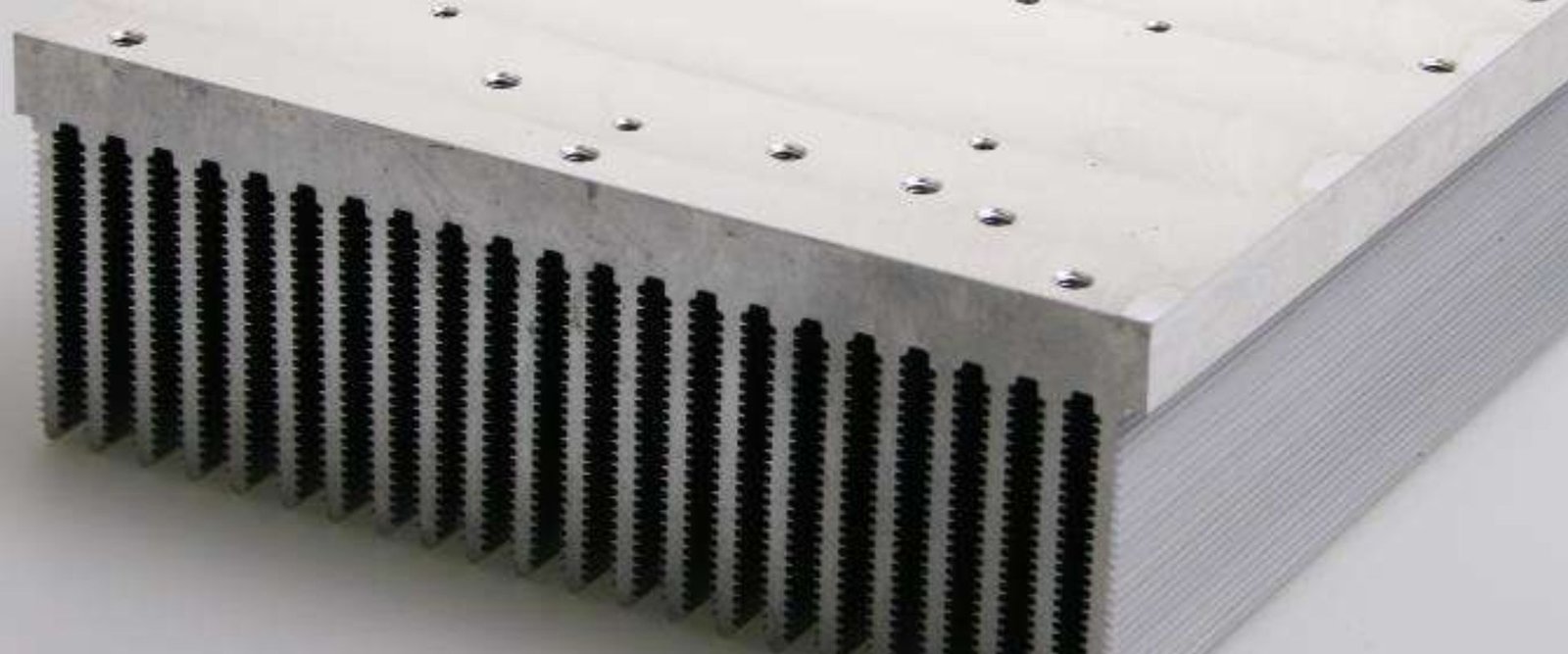

KIMSEN’s Aluminum Extrusion Heat Sinks are engineered to provide reliable and efficient thermal management across various applications. Using precision extrusion technology, these heat sinks deliver optimal heat dissipation, ensuring components remain cool and performance remains stable. Crafted from high-grade aluminum, they are lightweight, durable, and tailored to meet diverse cooling requirements.

Specification

Product Details

specification

Rigorous Quality

Reliable, high-performance materials and craftsmanship.

- Technology

- Advance Manufacturing

- Materials

- KIMSEN’s Expertise

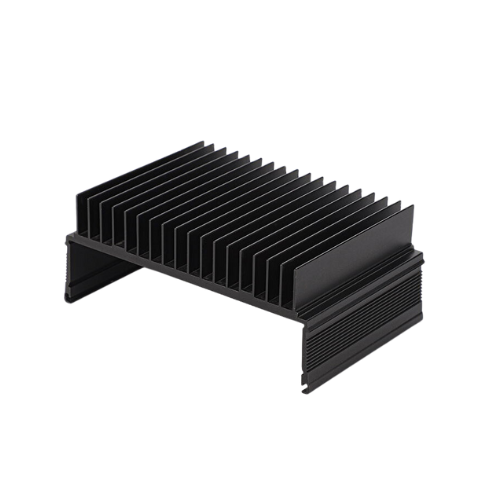

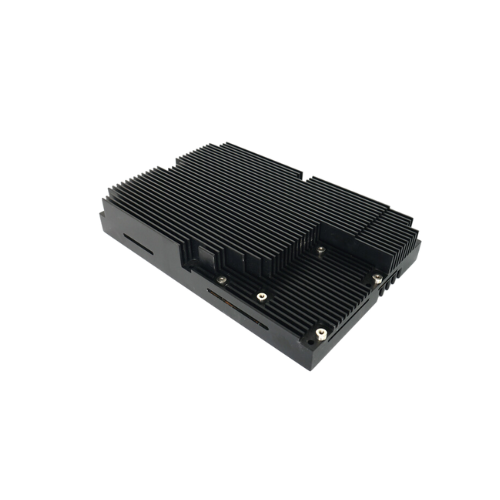

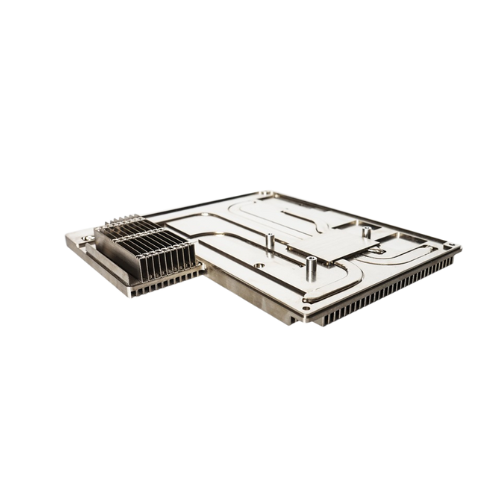

Our Aluminum Extrusion Heat Sinks leverage advanced extrusion methods, allowing for complex fin profiles that maximize surface area and improve heat transfer. This method provides greater flexibility in shape and size, enabling KIMSEN to create custom designs that meet specific cooling needs for a variety of applications, from electronics to telecommunications.

KIMSEN offers Aluminum Extrusion Heat Sinks in various profiles and dimensions, ensuring compatibility with a range of applications. Whether for small electronic devices or larger industrial machinery, our team works closely with clients to design custom profiles that enhance airflow and meet specific cooling challenges.

KIMSEN selects high-quality aluminum alloys known for their excellent thermal conductivity and durability. These alloys ensure that heat is effectively dispersed from critical components, while the material’s lightweight nature is ideal for applications where weight is a key consideration.

Each extrusion undergoes strict quality checks to ensure consistent performance, longevity, and resistance to corrosion, even under demanding operational conditions.

With a commitment to high-quality production standards and customer satisfaction, KIMSEN’s Aluminum Extrusion Heat Sinks represent our dedication to advancing thermal technology. Our streamlined manufacturing process, rigorous testing, and quality assurance ensure every heat sink meets the demands of modern industrial and electronic applications.