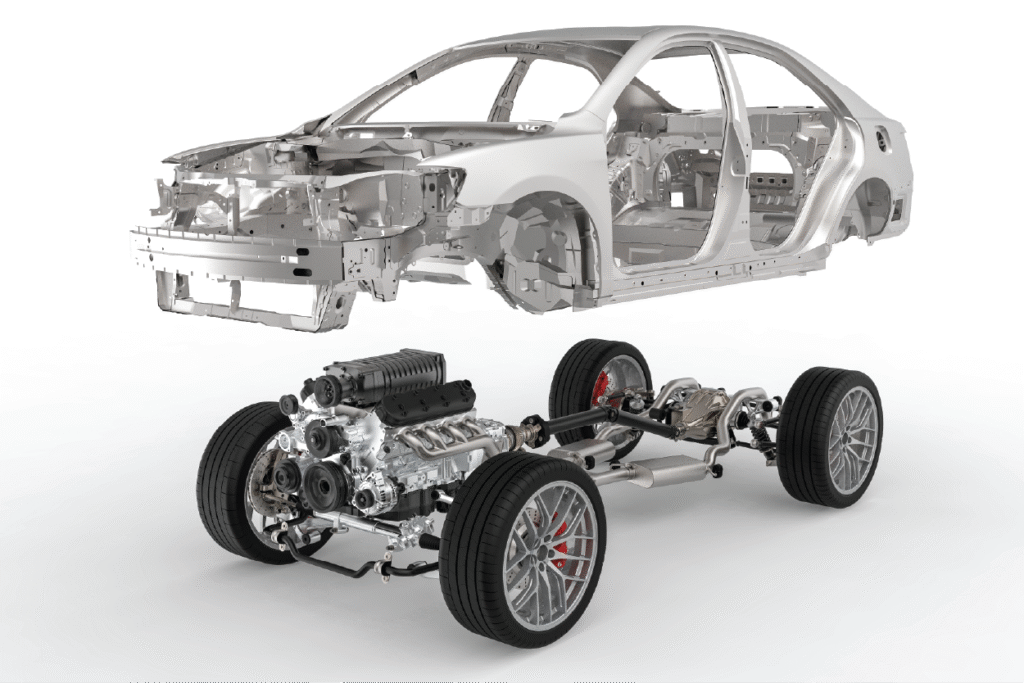

Aluminum may not be flashy, but it’s quietly revolutionizing how vehicles are built. From battery enclosure aluminum extrusions to crash-absorbing side rails, automotive aluminum components are the unseen workhorses of today’s vehicles. In 2025, with the push for lighter, smarter EVs, these parts are in high demand—especially from Vietnamese leaders like KIMSEN Industrial Corporation.

Why Automotive Aluminum Components Are Reshaping the Future of Cars

Lightweight Aluminum Parts for Better EV Range & Efficiency

Reducing weight is the fastest way to boost EV performance. That’s why lightweight automotive aluminum components like subframes and cross members are gaining ground in every major platform—from Tesla to Toyota.

Corrosion-Resistant Extruded Parts for Long-Term Durability

In harsh climates, extruded aluminum automotive parts last longer and require less maintenance—ideal for rocker panels, radiator brackets, and underbody reinforcements.

Sustainable Manufacturing with Recyclable Automotive Alloys

Automakers now value materials like automotive-grade aluminum for their low lifecycle emissions—especially in the EU, where green vehicle regulations are tightening in 2025.

High-Performance Alloys Used in Extruded Aluminum Automotive Parts

6000-Series Alloys: The Backbone of Battery Enclosure Aluminum Extrusion

From 6061 to 6082, these alloys dominate due to strength, machinability, and corrosion resistance—ideal for battery enclosure aluminum extrusions and structural rails. KIMSEN produces these profiles with consistent wall thickness and clean anodizing.

7000-Series Alloys in Structural Aluminum Car Components

When stiffness and fatigue resistance matter—think suspension arms or crash tubes—7075 aluminum outperforms. It’s the go-to for lightweight yet high-strength builds.

2000-Series Aluminum in Machined Drivetrain Housings

Less common but still critical in racing and high-performance applications, these alloys handle torque and vibration well in automotive aluminum drivetrain parts.

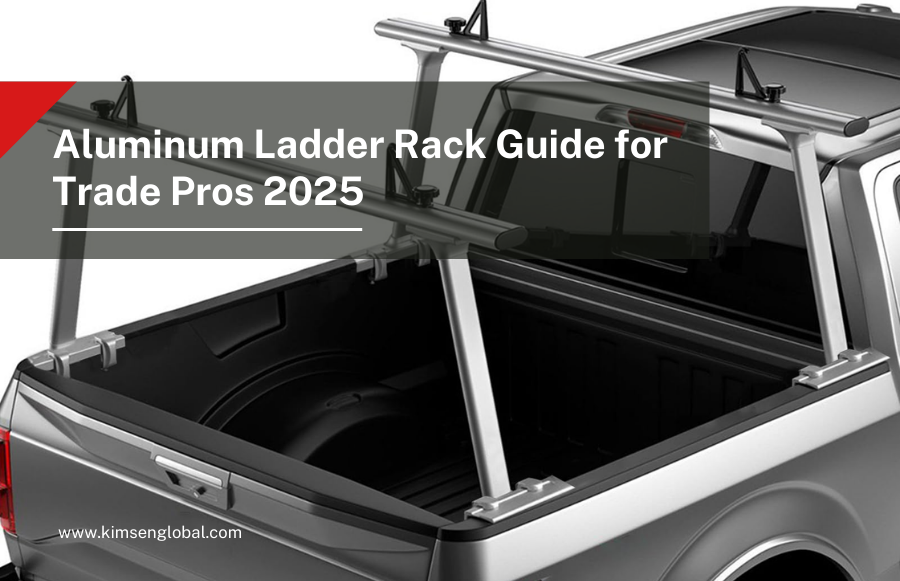

Little-Known Lightweight Automotive Aluminum Components in Action

Battery Tray and Sill Assemblies from Custom Aluminum Extrusions

EVs rely on battery enclosure aluminum extrusion to protect critical systems. These sill rails and trays must balance structural strength with thermal conductivity—something KIMSEN specializes in.

Crash Boxes, Bumper Beams & Side Impact Rails

Not every hero wears a badge. These hidden extruded aluminum automotive parts absorb energy and keep occupants safe—especially under Euro NCAP and NHTSA crash standards.

Radiator Mounts & Heat Exchanger Structures

Lightweight aluminum brackets help secure radiators and HVAC modules, resisting corrosion and vibration while shaving kilograms off vehicle mass.

Structural Rocker Panels and Side Sills

Often hidden beneath cosmetic body panels, these automotive aluminum components enhance torsional rigidity and lateral crash resistance.

Why Vietnam Aluminum Suppliers Like KIMSEN Excel in Automotive Components

Vietnam: A Rising Star in Global Automotive Aluminum Sourcing

With Section 232 tariffs on Chinese goods and Ukraine-related steel volatility, Vietnam is now a preferred hub. It offers cost-efficient, tariff-free automotive aluminum parts with short lead times.

KIMSEN Industrial Corporation: Leading Manufacturer of Extruded Automotive Components

Located in Bắc Ninh, KIMSEN delivers:

-

- In-house CNC machining, robotic welding, anodizing

-

- ISO 9001:2015, IATF 16949 certifications

-

- Specialization in custom battery tray extrusions and structural rails

KIMSEN’s ability to combine flexible design, high-volume output, and export reliability puts them among Vietnam’s top-tier automotive aluminum suppliers.

>> Read more: Aluminum Car Body Solutions from Vietnam

Case Studies: Real Applications of Extruded Aluminum Automotive Parts

Tesla Cybertruck: A Fusion of Cast and Extruded Aluminum Parts

While its exoskeleton is steel, the inner support system includes extruded sill rails and underbody frame members—similar to those from Vietnam aluminum suppliers.

Ford F-150: From Lightweight Panels to Structural Cross Members

It’s not just the body panels—automotive aluminum components like crash boxes, bumper brackets, and steering supports are now lightweight extrusions.

Audi’s Lightweight Legacy: A2 and A8 Use Advanced Extrusions

Audi’s early adoption of lightweight aluminum chassis parts paved the way for today’s EV-focused designs.

Meeting Standards: What Defines Automotive-Grade Aluminum Components?

What Makes a Component “OEM-Grade” Aluminum?

-

- Tight tolerances (±0.05mm)

-

- Consistent grain structure and heat treatment (T5/T6)

-

- Proven performance in crash and corrosion tests

KIMSEN performs 100% dimensional inspections, salt spray testing, and CMM checks on all batches.

Must-Have Certifications for Automotive Aluminum Suppliers

-

- ISO 9001:2015 for quality assurance

-

- IATF 16949 for automotive compliance

-

- Full traceability on alloys, heat numbers, and machining processes

In 2025, compliance is no longer optional—it’s table stakes for entering global auto supply chains.

2025 Trends in Automotive Aluminum Extrusions and Component Design

Growing Use of Battery Enclosure Aluminum Extrusions in EV Platforms

OEMs need flexible, scalable extrusion profiles to house battery modules. Custom shapes reduce assembly complexity—KIMSEN offers tailor-made designs with CNC-finishing ready.

Lighter, Safer, Smarter: The Evolution of Lightweight Automotive Aluminum Components

Even pedals, brackets, and seat supports are going aluminum—shedding grams while enhancing strength.

Sourcing Stability Amid Trade & Conflict Disruptions

The ongoing Ukraine conflict and inflation spikes in 2025 have tightened global supply chains. Sourcing from stable hubs like Vietnam ensures consistent delivery and pricing.

Key Takeaways

-

- Automotive aluminum components include essential yet hidden parts like battery trays, rocker panels, and crash boxes.

-

- Lightweight aluminum extrusions improve EV range and crash performance.

-

- Vietnam’s aluminum sector, led by KIMSEN, offers competitive quality without tariff headaches.

-

- The most common alloys are 6000- and 7000-series—machinable, strong, and corrosion-resistant.

-

- Quality and traceability are essential—look for ISO and IATF certifications.

-

- EV trends, global policy, and modular architecture are accelerating aluminum adoption.

FAQs

Battery trays, side sills, bumper beams, and radiator mounts—extruded for weight and strength.

They offer OEM-quality components, short lead times, and tariff-friendly pricing—especially for U.S. and EU buyers.

It forms the protective frame around battery packs—combining structural integrity with heat dissipation.

More shape flexibility, lower weight, and improved corrosion performance.

6000-series for general use; 7000-series for high stress; 2000-series for specialized machining.